E-mail:sales@bestchickencage.com

E-mail:sales@bestchickencage.com

Summary

Poultry farm equipment refers to the tools and systems used in poultry farming to ensure efficient operations, improve productivity, and maintain the health of the birds

Poultry farm equipment is essential for efficient and productive poultry farming. It includes housing systems like a-type and h-type cages, feeding and watering systems to ensure proper nutrition and hydration, and automated egg collection to reduce labor. Climate control equipment like fans, cooling pads, and heaters maintain a healthy environment, while waste management systems handle manure efficiently. Hatchery equipment like incubators supports egg hatching. These tools improve farm operations, ensure bird welfare, and maximize productivity

Poultry farm equipment is designed to improve efficiency, bird health, and productivity. It includes cages, feeders, drinkers, egg collection systems, climate control tools, and waste management systems. Automated systems for feeding, watering, and manure removal reduce labor and enhance hygiene. Climate control ensures proper ventilation and temperature, while hatchery equipment supports egg incubation. These tools are essential for modern poultry farming, ensuring higher efficiency and profitability

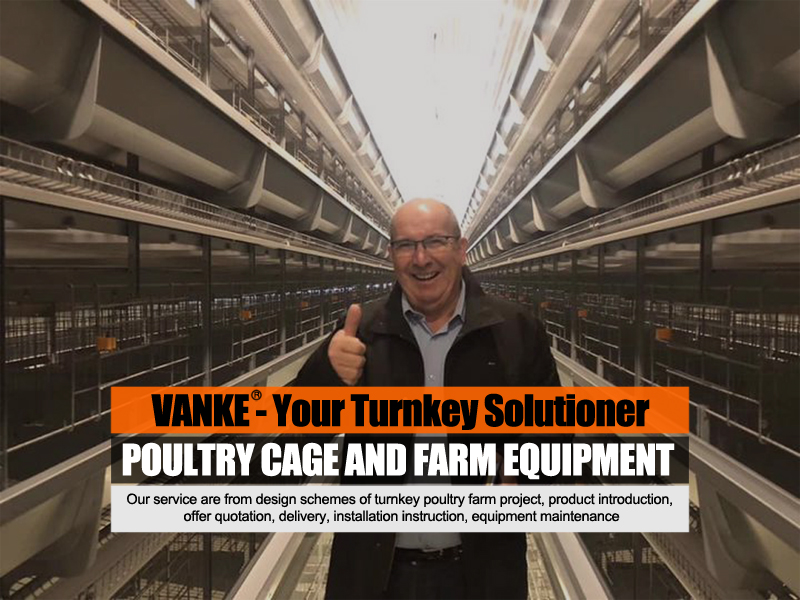

We offers innovative and reliable solutions that address the growing demands of modern poultry farms. From egg production to broiler farming, our automated systems help increase productivity, improve bird health, and streamline farm operations. With durable, scalable, and efficient equipment, we provide poultry farmers with the tools needed to optimize operations, reduce costs, and enhance both egg and meat production. Whether you are a small farm or a large commercial operation, our equipment offers practical solutions to enhance your poultry farming business

Poultry farm equipment

The production process steps for poultry farm equipment:

1. Design and planning: Create detailed equipment designs.

2. Material selection: Choose galvanized steel, plastic, or pvc for durability

3. Fabrication: Cut, mold, and shape materials into components

4. Welding and assembly: Assemble parts into complete systems

5. Surface treatment: Apply galvanization for rust resistance

6. Quality control: Test for durability and functionality

7. Packaging and distribution: Pack and ship equipment to customers

Let us send you the required information by post. Just click on this link to let us know which products you are interested in

1. Automatic poultry cage system

Bookmark our website and leave message on our website now to getting guiding to choosing right poultry equipment and enquiry for your poultry farm, we are the designer, manufacturer and supplier of poultry farm turnkey projects

The production process of poultry farm equipment involves designing, material selection, fabrication, welding and assembly, surface treatment, quality control, and packaging. High-quality materials like galvanized steel and plastic are used to ensure durability and functionality. Components are cut, shaped, welded, and assembled into finished products such as cages, feeders, and drinkers. Surface treatments like galvanization provide rust resistance, and rigorous quality checks ensure reliability. Finally, the equipment is packaged and distributed to farms for installation

Parameters

|

Parameter |

Description |

|

Material |

Galvanized steel, plastic, pvc, or polypropylene (pp) |

|

Durability |

15–20 years with proper maintenance |

|

Capacity |

Equipment size depends on farm scale (e.g., cages hold 60–120 birds per unit) |

|

Automation level |

Manual, semi-automatic, or fully automatic systems |

|

Dimensions |

Customizable sizes for cages, feeders, and drinkers |

|

Power requirements |

220v/380v for automated systems |

|

Galvanization |

Zinc coating thickness: 275 g/m² (standard for corrosion resistance) |

|

Feeding system |

Feed conveyors or manual troughs |

|

Drinking system |

Nipple drinkers or bell drinkers |

|

Manure removal system |

Automatic belt conveyor for waste handling |

|

Ventilation system |

Fans, cooling pads, or natural airflow |

|

Weight |

Varies by equipment size (e.g., cages: 300–800 kg per unit) |

|

Egg collection |

Conveyor belts for automated egg collection |

|

Parameter |

Description |

|

Material |

Galvanized steel, plastic, pvc, or polypropylene (pp) |

Our services

1. We offer tailored solutions based on farm size, capacity, and requirements

2. We offer expert assistance for on-site assembly and setup

3. We offer regular maintenance, troubleshooting, and spare parts supply

4. We provide professional advice on equipment selection and farm layout optimization

5. We provide hands-on training for staff on equipment operation and management

6. We also provide dedicated support for long-term equipment performance and customer satisfaction

Frequently asked question

Q: What is poultry farm equipment?

A: Poultry farm equipment includes tools and systems like cages, feeders, drinkers, egg collectors, and climate control systems designed to improve poultry farming efficiency and bird welfare

Q: What are the main types of poultry farm equipment?

A: Key types include housing systems (a-type or h-type cages), feeding and watering systems, egg collection systems, climate control equipment, and waste management systems

Q: How is waste managed in poultry farms?

A: Automatic manure belts and drying systems are used to remove and process waste efficiently, reducing odors and promoting hygiene

SEND YOUR MESSAGE TO US

(* We will reply your inquiry to this Email as soon as we see it.)RECENT BOLGS

CONTACT US