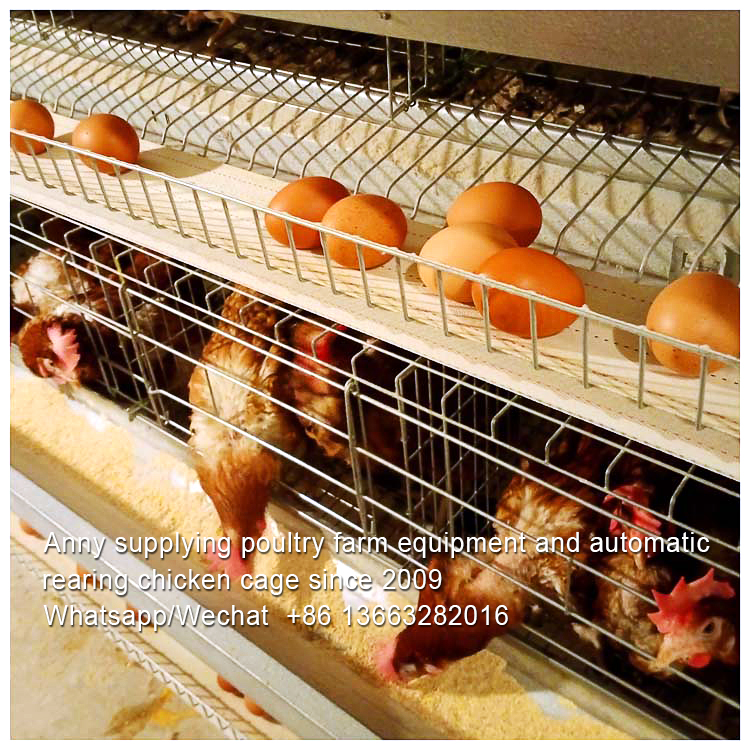

Manure Dryer can dry poultry manure / Chicken litter moisture. It is suitable for the storage and production of organic fertilizer. It operates a closed system, thus reducing the influence on the environment. The poultry manure dryer machine also can be used to dry other kinds of animal manure such as cow dung, etc. It is imported. It has a capacity of 1 tonne per hour. The Scraper Type Manure Collection System is designed for A frame cage systems which has manure pits under the cages. The manure dropping from the cages in the manure pits, and the manure scraper can collect the manure outside of the chicken house.

The System Advantage:

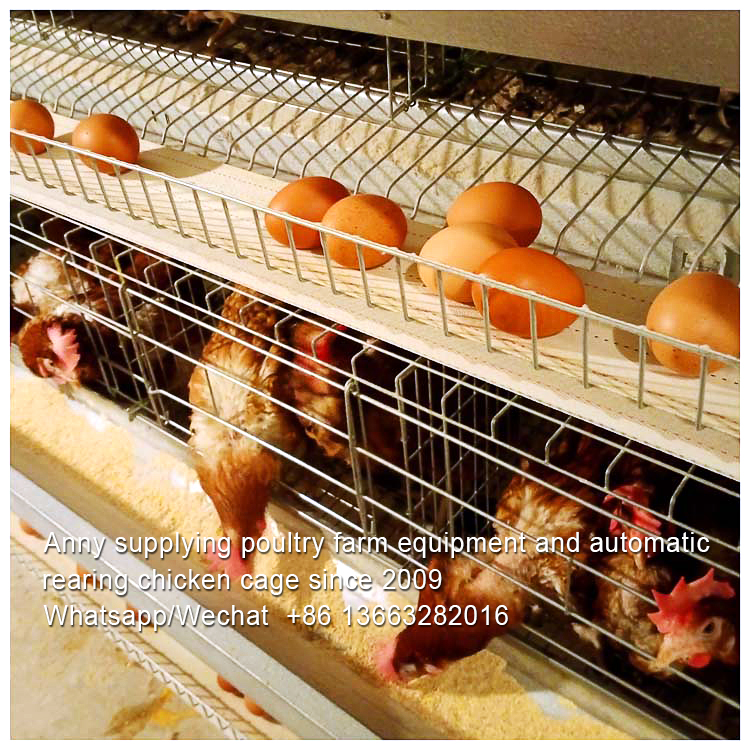

● Special design for A frame Cage System with manure pits under the cages, the various width of manure scraper are available.

● Lower cost and easily to operate by control panels.

● Solid structure and durable because of hot dipped galvanized manure scrapers and imported Nylon connection hemp ropes.

● saving more labour works and cleaning the chicken house inside immediately in order to control the ammonia emission.

Manure dryer for poultry heats and adopts the counter current drying principle to achieve the purpose of drying. This machine is widely used for drying. It can be used for drying particles of loose materials. It is found to be effective in the agricultural, feed, chemical, power or light, food and other industries. This manure dryer is mainly composed of pipes rotor at both ends of bearing. It also comes with bearing pedestal, roller, roller ring, motor, gear combination, shovelling plate, girder, shell, cylinder gear reducer etc. The Motor Drive and the tube rotor rotate through cylindrical gear reducer and the gear rotate system.

This machine has an up inlet and a set inlet when poultry manure is dropped into it, the feeding belt transports it. Inside of the manure dryer, there are many tubes. During the drying process, the hot air will enter into the internal tube by the draught fan. Then the shovelling plates, which are installed outside of the heating pipes, grab and push the dried material forward from the inlet to outlet slot.

Advantages of Using This Manure Dryer for Poultry:

●Low energy consumption

●There is no cause for heating installations

●There is a drastic reduction in ammonia content

●There is no need to dry the manure with a battery

●Low residual water content

●Low costs for the installation

Working Principle

Moisture content 50-65% raw material put into mixing drum dryer by a screw conveyor for downstream drying, the material will be constantly lifting by lifting plate, then Scattered in a spiral type marching forward, this type dryer is equipped with a high -speed broken devices in the roller, it can fully mixing scattered and broken the material, the material and hot air will heat exchange, the water will quickly evaporation and gasifier, the material which achieved the drying effect will be quickly moving and fast discharge under hot air action, other material which not achieved drying effect will moving slowly under self- weight, the material will fully dry inside of drum ,have a good drying effect and complete the drying process and put out by screw conveyor. Inside of this type drum dryer is equipped with shaking and cleaning devices, this can prevent material adhesive on dryer body.

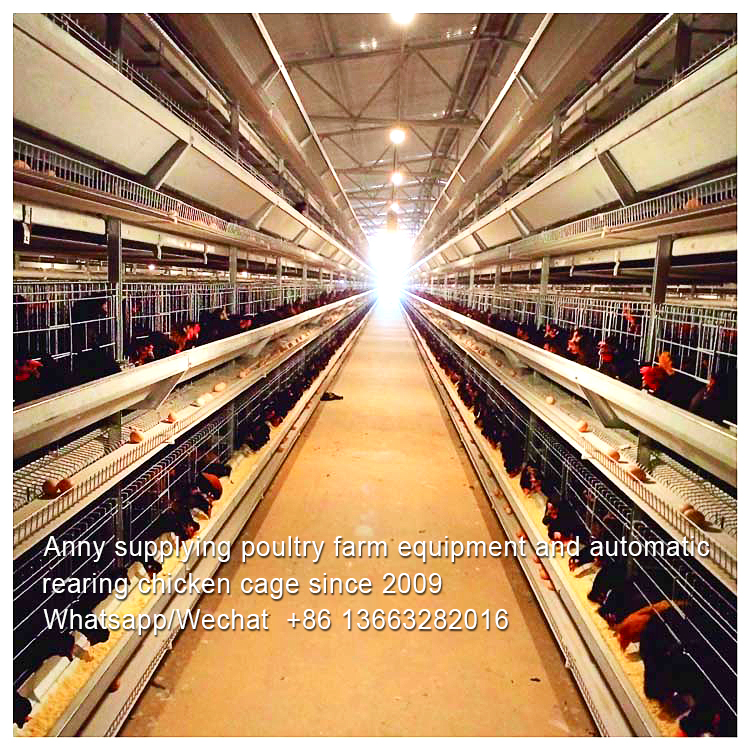

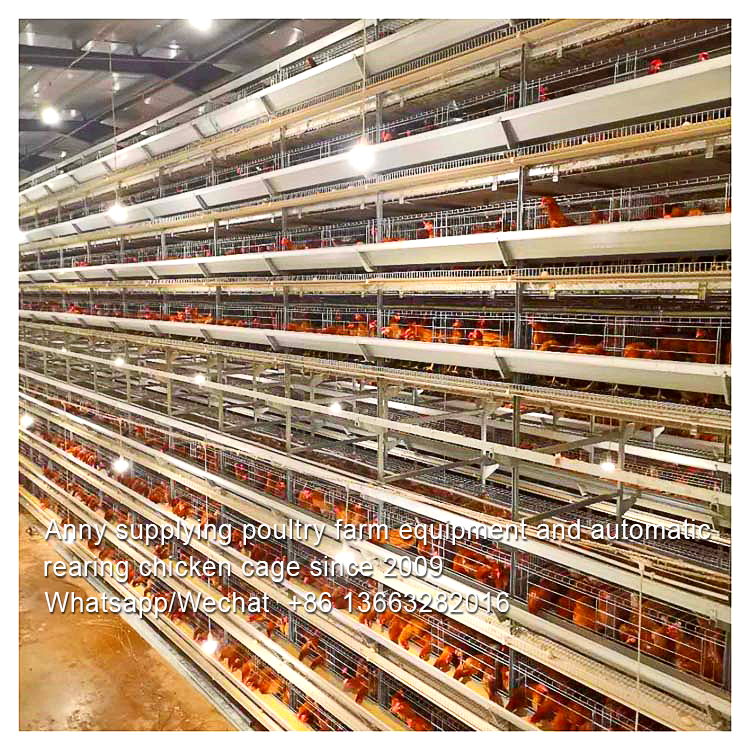

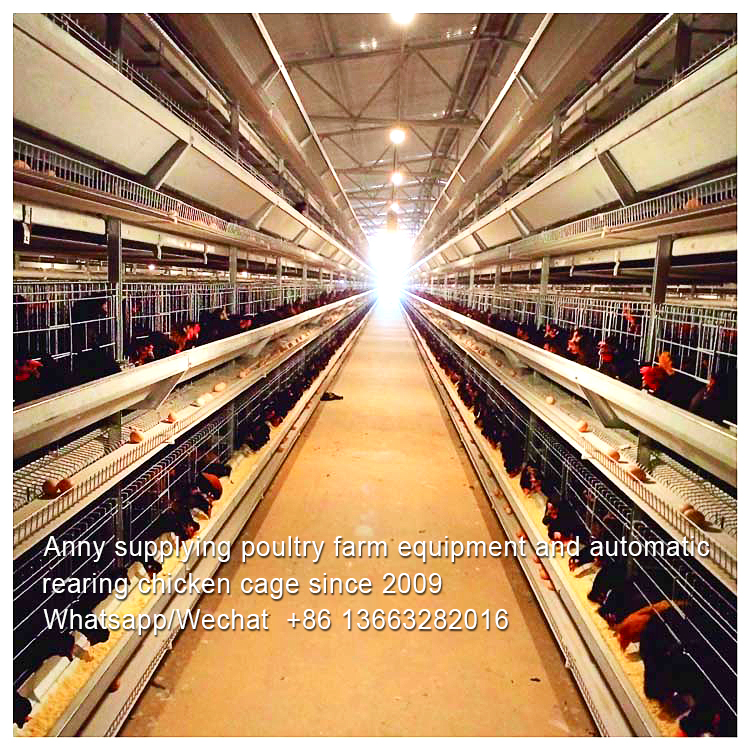

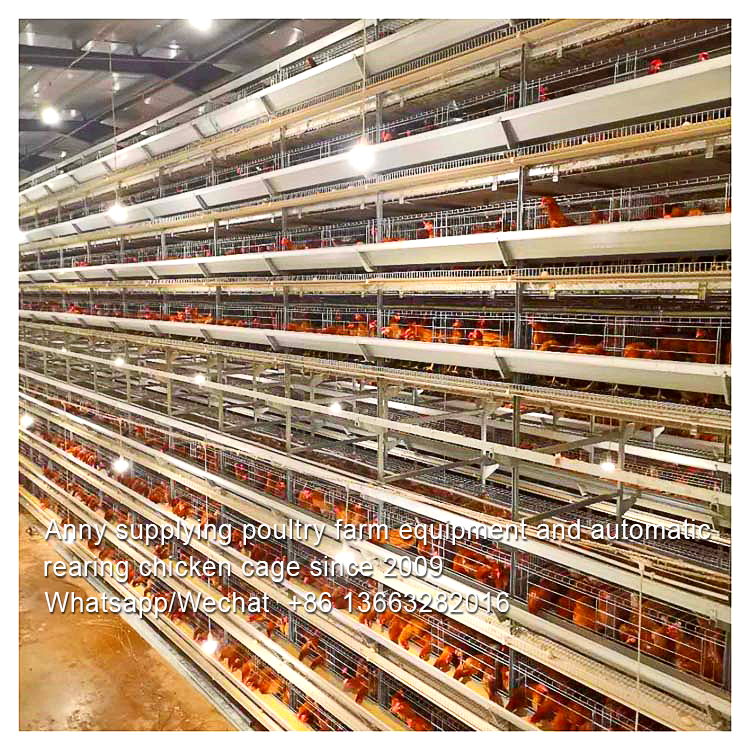

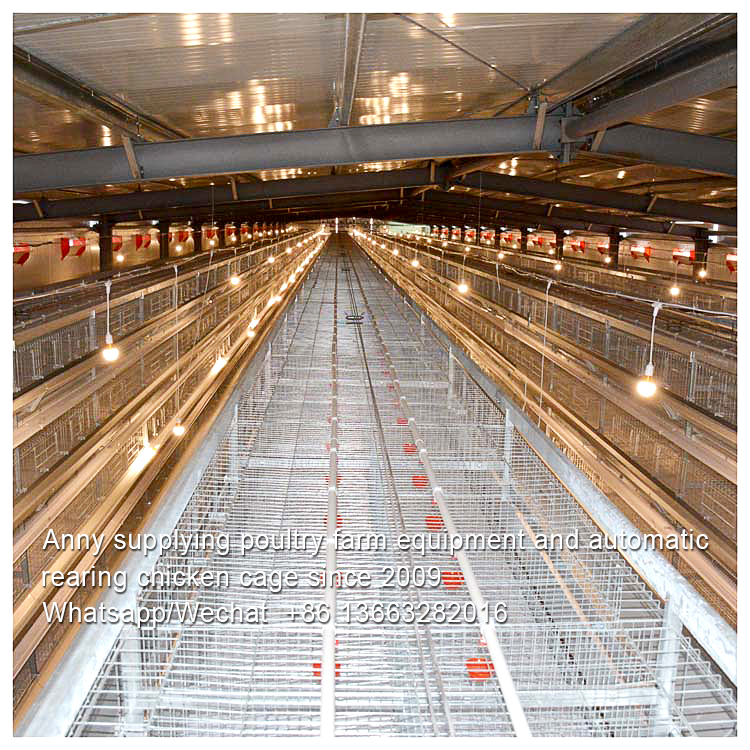

Our China chicken cages and poultry equipment Factory

Hebei Best Machinery And Equipment Co., Ltd.,found in 1996, 360KM from BEIJING city, from raw materials to finished products, strict implementation of ISO 9001:2008 quality management system.

Our Nigerian branch chicken cages and poultry equipment Factory

Rose of Sharon Plaza by Oko filing bus stop, Igando road, opposite Oando filling station, Lagos, production line is from our Chinese factory directly, 3 to 5 years longer using than local battery cages.

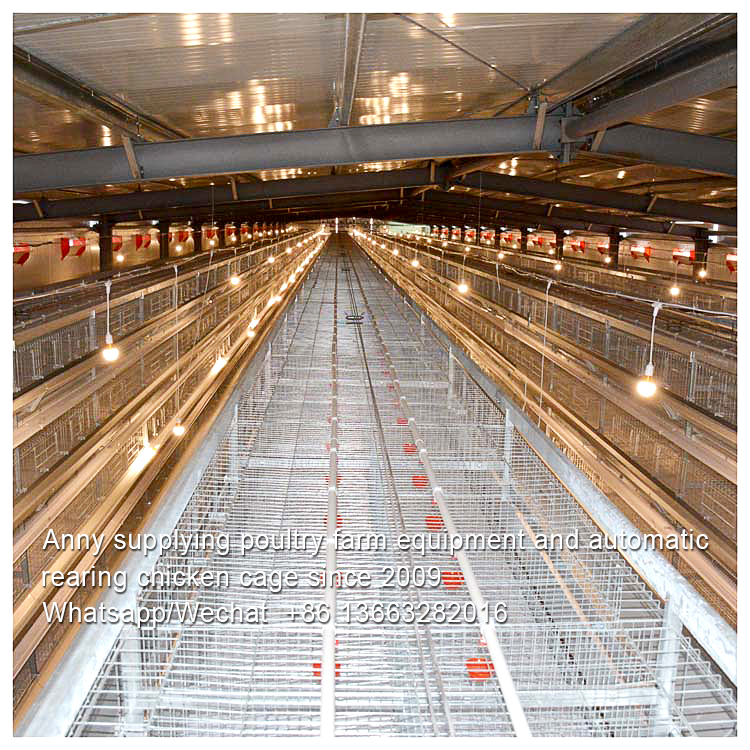

If you have any plan on poultry farm, please free to contact me, I supplying farm equipment and automatic rearing battery cage since 2009.

Anny Wang, Whatsapp/Wechat +86 13663282016