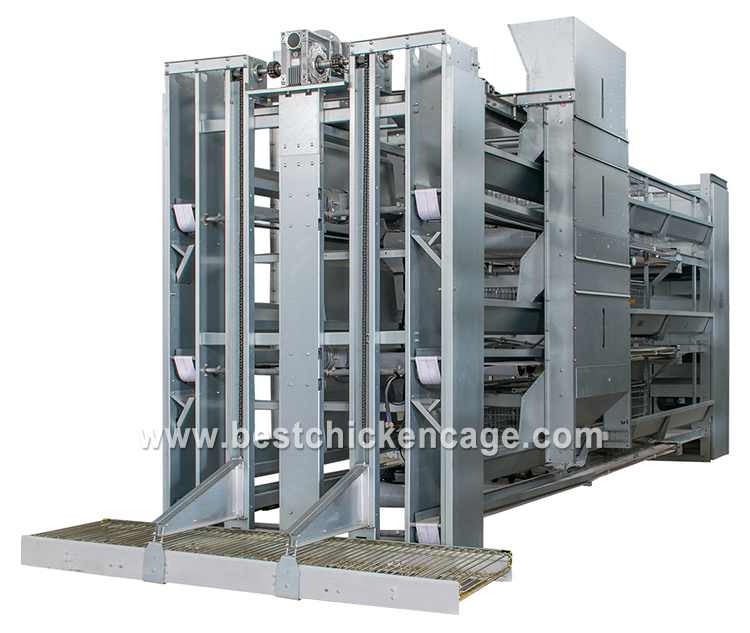

8 tiers of automatic egg layer chicken cage

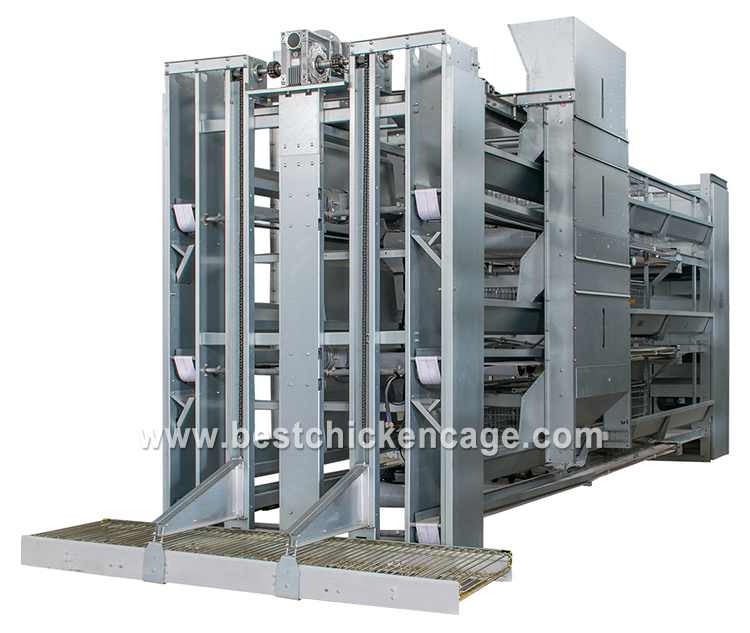

4 tiers of automatic egg layer chicken cage

Relevant corollary equipment

Electric control cabinet

Feeding system

Drinking system

Egg-collection system

Manure removal system

Sidewall ventilation windows

Ventilation fans and cooling pads

Farm application

This is a kind of high-end chicken cage, serving 100,000 birds to 1,000,000 birds or more, 5 poultry houses or even more, usually widely used in developed countries or mechanical automation countries

If you are interested in other poultry equipment for your farm, please directly click PRODUCTS

Specification

The Normal Specifications of Cages

1. Cage Dimension/Cell:(390--490)*(350--500)*(380--430)mm,5cells/Unit,

2. 6(3tiers)/8(4tiers)units/sets.

3. Installed Dimension/sets:2000*1200*410mm.

4. Total Floor Area per cell:430--500 sq.cm;total Birds/Cell:3--5 birds; 450 sq.cm/bird.

5. Battery Cage Dimension:any dimension of Cages are available from clients.

Battery Cage System tiers: 2--5 tiers optional available.

Why VANKE®

With state of the art facilities,powerful R & D team and rigorous quality management system, VANKE has owned undoubtedly the strength to become your preferred partner to build modern automated poultry farms.In addition,we have an experienced,quick-response project team which helps customers with poultry farm location planning,chicken house design and construction and equipment installation as well as provides product upgrade and free technical consulting services

Project

Vanke Machinery & Equipment Nig Ltd have serviced farmers and distributors since 2010, Location is Rose of Sharon Plaza by oko filling bus stop Igando Lagos, for your farm project our service are chicken farm project design, chicken cage layout, delivery, installation of chicken cage and poultry equipment

Please contact +234 8111199996

Whatapp to +234 8111199996, 24 hours online

Email to sales@bestchickencage.com

Or leave message to the web page

Advantage

Advantages

1. More Suitable to use in rain-less district,durable and solid structure for long lifetime

2. Easily to deliver and installation in clients farm and make maintenance

3. Prompt steps to control feed wastage because of the longer design feed trough edge

4. The cage method of housing is ideal for the area of moderated climate conditions where the day temperature in summer is not high or fall too low

5. The overlap parts is smaller so the chicken house can get much better ventilation,it can be used both in open or close house according clients’ needs

Package

The cage and frame are no package , some fittings are in plastic bags and carton box

Maintaining

1. After finish installation, clean the feeding trough

2. Connect water, to make sure the whole drinking system is well from row beginning to end

3. After 2 years using, move all birds, clean the cage mesh

4. Replace the nipple drinkers if they link water to protect brid feather, medicinal water will make feather fall off

5. Check control cabinet, all belts, motor of feeding, egg collection and manure removal and so on, our technicists will teach yours after installation.