A hatchery is a central place where the hatching egg is transformed during 21 days into a one-day-old chick or into a one-day old-poultry in 28 days. All parameters to make this transformation possible are unfortunately also ideal for the growth of bacteria and moulds: temperature, water, oxygen and nutrients. Hence, it is more than obvious that efficient hygiene is important in order to minimize harmful bacteria and mould exposure on the egg or the chick

Care must be taken to maintain humidity during the hatching period. Unobstructed ventilation holes, both above and below the eggs, are essential for proper air exchange. Eggs must be turned at least 4-6 times daily during the incubation period. Poultry production, being a series of specialist entities, requires that each in turn is carried out correctly, in order to achieve the ultimate goal, which is to produce a chicken of the best quality in the least time and under the optimal environmental conditions that will allow the chick to grow stress free, and perform to its maximum genetic potential. In order to achieve this, a series of events need to be strictly adhered to by all the relevant links in this production chain.

For the best hatching results, the fertile eggs produced need to be collected frequently and the eggs transferred to an egg holding facility where the egg temperature is required to be kept at 24°C. Do not turn eggs during incubating any bird egg. It is important to control the same factors of temperature, humidity, ventilation, and egg turning. Poor results are most commonly produced with improper control of temperature and/or humidity. Improper control means that the temperature or humidity is too high or too low for a sufficient length of time that it interferes with the normal growth and development of the embryo. Poor results also occur from improper ventilation, egg turning and sanitation of the machines or eggs.

Obtain the best hatch by keeping the temperature at 100º F. throughout the entire incubation period when using a forced-air incubator. Minor fluctuations (less than ½ degree) above or below 100 degrees are tolerated, but do not let the temperatures vary more than a total of 1 degree. Prolonged periods of high or low temperatures will alter hatching success. High temperatures are especially serious. A forced-air incubator that is too warm tends to produce early hatches. One that runs consistently cooler tends to produce late hatches. In both cases the total chicks hatched will be reduced.

Maintain a still-air incubator at 102 degrees F. to compensate for the temperature layering within the incubator. Obtain the proper temperature reading by elevating the bulb of the thermometer to the same height as the top of the eggs when the eggs are laying horizontal. If the eggs are positioned in a vertical position, elevate the thermometer bulb to a point just below the top of the egg. The temperature is measured at the level where the embryos develop (at the top of the egg). Do not allow the thermometer's bulb to touch the eggs or incubator. Incorrect readings will result. Humidity is carefully controlled to prevent unnecessary loss of egg moisture. The relative humidity in the incubator between setting and 3 days prior to hatching should remain at 58-60 percent or 84-86º F., wet-bulb. When hatching, the humidity is increased to 65 percent relative humidity or more. Rarely is the humidity too high in properly ventilated still-air incubators. The water pan area should be equivalent to one-half the floor

surface area or more. Increased ventilation during the last few days of incubation and hatching may necessitate the addition of another pan of water or a wet sponge. Humidity is maintained by increasing the exposed water surface area.

Ventilation is very important during the incubation process. While the embryo is developing, oxygen enters the egg through the shell and carbon dioxide escapes in the same manner. As the chicks hatch, they require an increased supply of fresh oxygen. As embryos grow, the air vent openings are gradually opened to satisfy increased embryonic oxygen demand. Care must be taken to maintain humidity during the hatching period. Unobstructed ventilation holes, both above and below the eggs, are essential for proper air exchange.

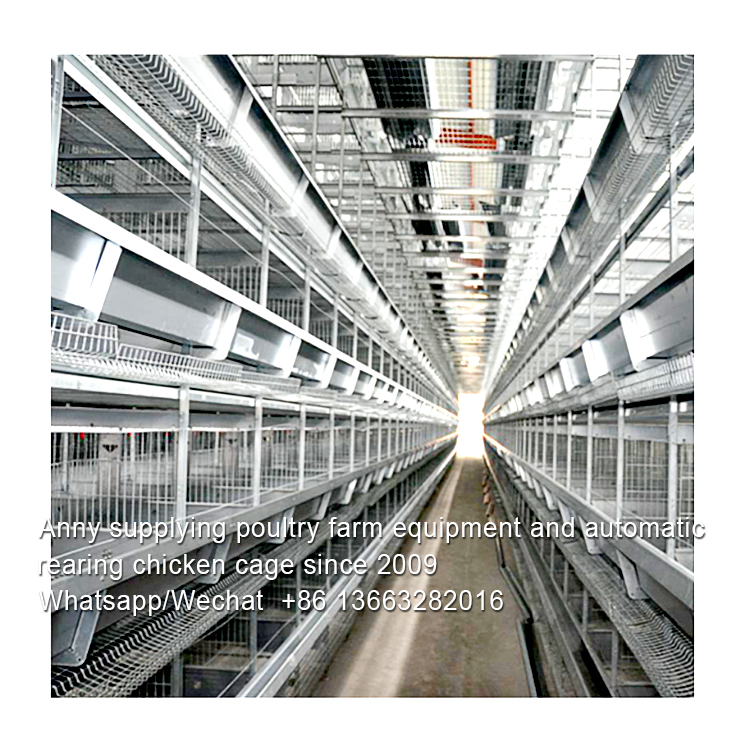

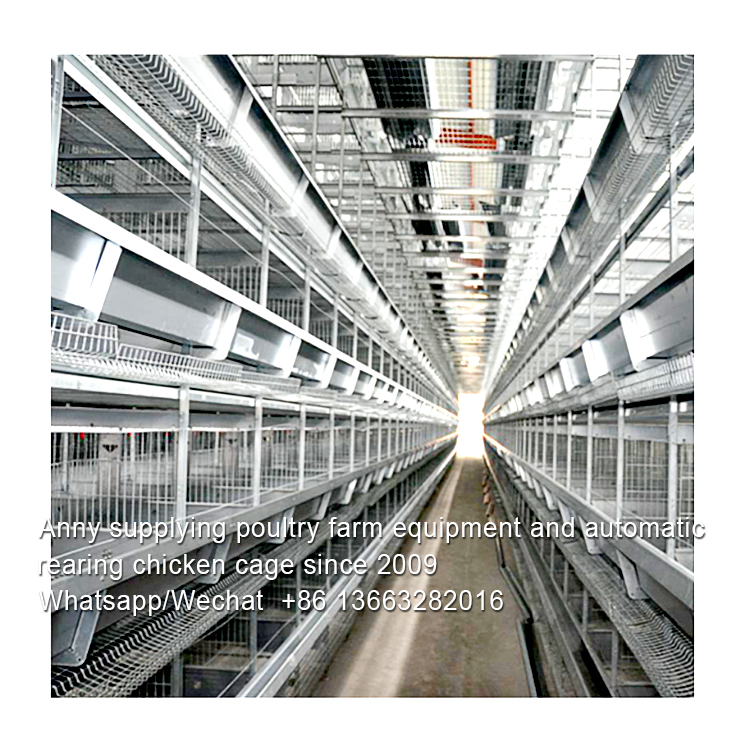

Our China broiler chick cage and poultry equipment Factory

Hebei Best Machinery And Equipment Co., Ltd.,found in 1996, 360KM from BEIJING city, from raw materials to finished products, strict implementation of ISO 9001:2008 quality management system.

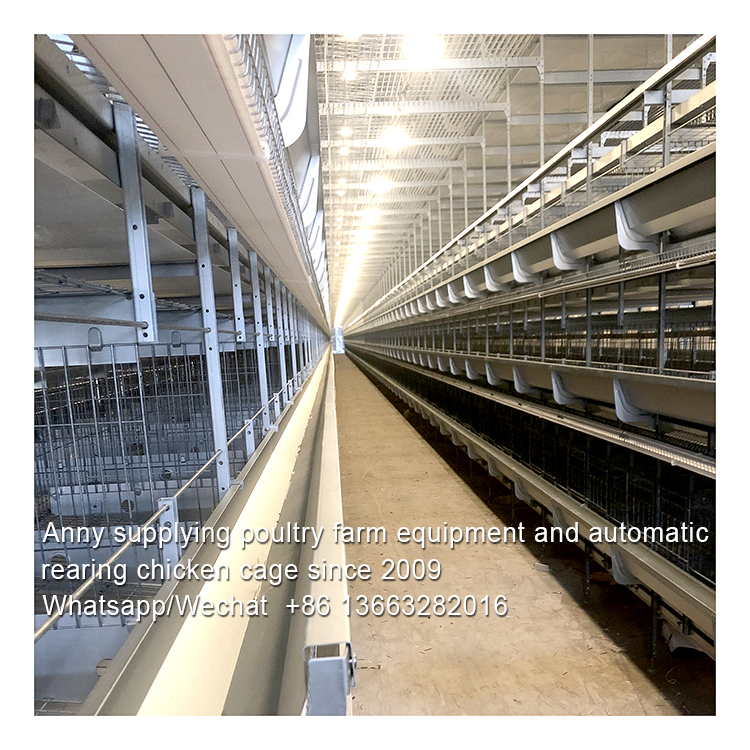

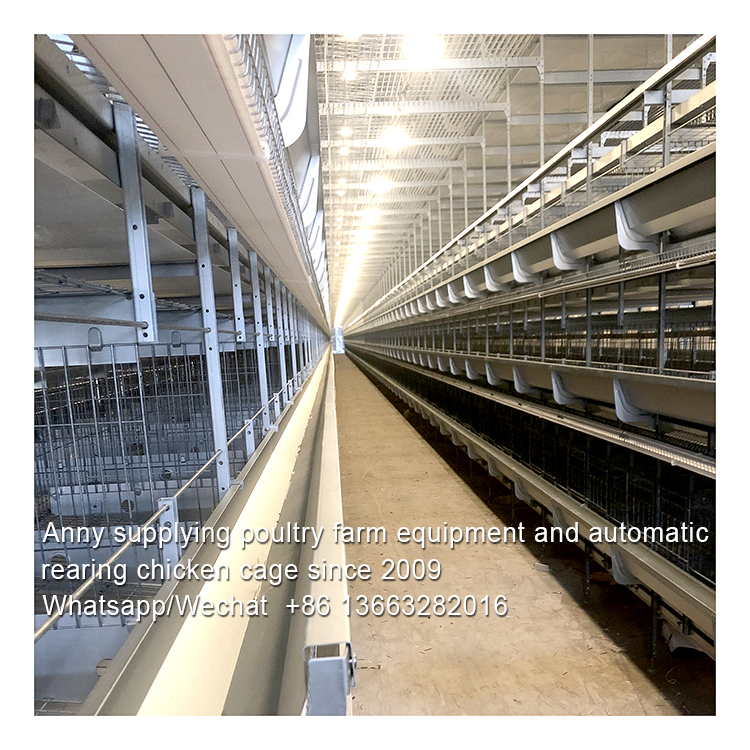

Our Nigerian branch broiler chick cage and poultry equipment Factory

Rose of Sharon Plaza by Oko filing bus stop, Igando road, opposite Oando filling station, Lagos, production line is from our Chinese factory directly, 3 to 5 years longer using than local battery cages.

If you have any plan on poultry farm, please free to contact me, I supplying farm equipment and automatic rearing battery cage since 2009.

Anny Wang, Whatsapp/Wechat +86 13663282016